“Humankind was built on beer. From the world’s first writing to its first laws, in rituals social, religious, and political, civilization is soaked in beer.” –William Bostwick

Overview

In the Fall of 2011, I drove onto Poplar Street in Oakland, California, and parked in a lot next to a copper recycling plant, just down the way from an artisans collective supporting the Burning Man efforts. It is not a likely location for someone about to embark on a journey to discover some of the most attractive renewable energy projects built from the mid-1980s to the present day. I signed up to work on managing agricultural waste and making renewable energy to run farms and food plants while focusing on reduction and sustainability.

I sat across from a team of smart engineers, wearing flannel shirts, blue jeans, and Patagonia hoodies. Raw, funny, and hospitable - a group of renegades digging holes to collect food waste and manure effluent, covering it, and producing a slurry to make methane gas. About to dip my toe in the water, writing RFPs, and sales & marketing pieces for a company putting s$&t in a hole and miraculously turning it into electricity was uncharted territory for me. I would soon be responsible for the narrative. I clearly overdressed, quickly pulling off my suit jacket, trying to assimilate. They laughed, and we all got a kick out of my corporate sales and marketing polish, which I left behind across the Golden Gate.

Solid Waste Generation From Brewing Beer

I remember the smells of earthen salsa as we sat together. They ate their street tacos with Tapatio, and I drank a Pellegrino from the fridge. I didn't realize then that I fit in with some of the smartest people I know today. I set forth on working with this team, on and off, for just over five years. We built something together, autonomously, and sometimes on different continents. From them, I learned the importance of environmental challenges facing food, alcohol, and agricultural businesses around the globe. Producers are running and scaling their craft while simultaneously focusing on mitigating waste and creating a stamp of sustainability for their respective organizations. My research and writing began with working on Municipal Solid Waste (MSW), agricultural, and brewery Anaerobic Digesters (AD).

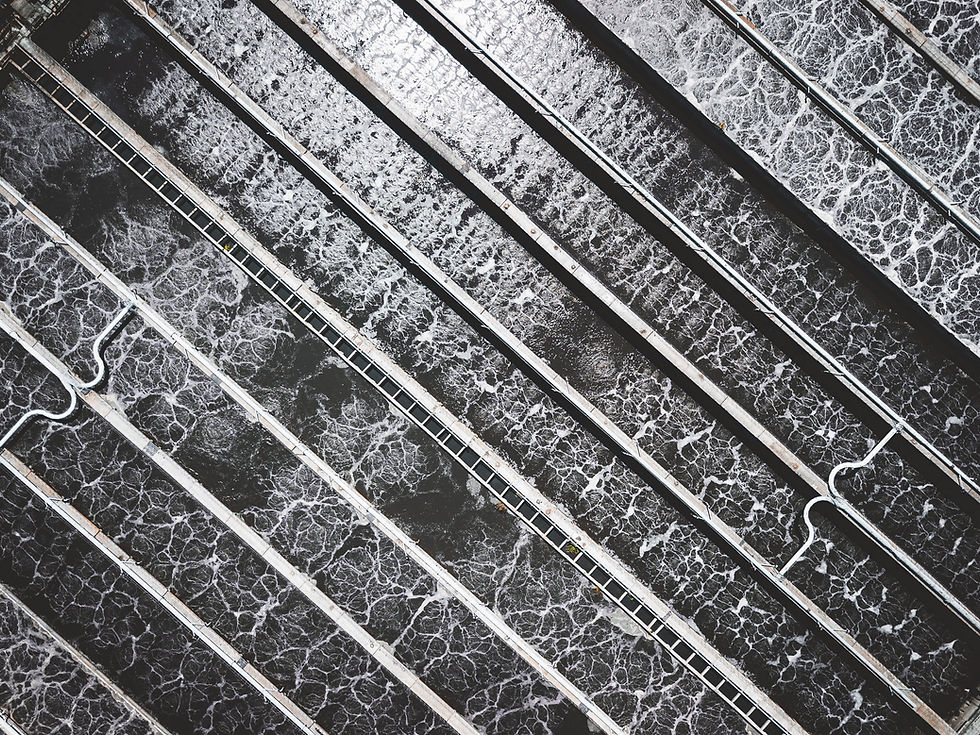

An anaerobic digester is an engineered process through which bacteria breaks down into organic matter under a specific ambient temperature without oxygen. In this case, food waste, manure, and brewer’s waste were topic du jour. I spent the first six months of my new venture visiting food plants, dump facilities, farms, distilleries, and breweries whose scale in the industry began to mandate a closer look at renewable energy and waste management.

Brewer’s Spent Grains (BSG) account for roughly 80% of a brewery’s waste stream. A waste stream is the brewing cycle's leftovers, solids, and liquids. Most of this byproduct goes to farms for feed or food manufacturers for commercial-scale bakery items. The leftovers of brewery waste are spent grains containing h20 & fermentable sugars. Spent Diatomaceous Earth (DE) is a natural, tasteless mineral that filters the brew but also becomes a waste byproduct downstream. Some brewers use it to change the characteristics of their flavor profiles. Spent Yeast (SY) is a byproduct arising from the cooking process. Spent Trub (ST) is from a German derivation, meaning sediment. It is formed from the wort boiling process, called hot break. These waste factors can be costly, and if a brewer has limited space, it can get messy.

Packaging and Food Service Solutions

The inputs to making beer are intense; packaging and food service events are massive waste builders. There are case studies where brewers have been making a difference for decades. For example, helping to refine MSW issues by creating waste collection efficiencies in the plant. Some consultants do this work with breweries, and others hire a staff manage operations. People on the front lines doing the work effort are invested in sustainability outcomes for their companies. The Brewers Association offers a comprehensive, 50-page document called Brewers Association - Solid Waste Reduction Manual. The association has built a comprehensive document with solid tools for creating recycling programs. They offer online Excel-based calculations and metrics for estimating cost and space consumption, feasibility for onsite composting, and a holistic approach to building a sustainability plan.

Beer Waste Into Renewable Energy Using AD

Anaerobic digestion (AD) is a viable way to deal with organic waste from brewing beer. When considering AD, installing a bioreactor significantly reduces energy costs and Greenhouse Gas (GHG) emissions. AD is a complex four-step process that includes hydrolysis, acidogenesis, acetogenesis, and methanogenesis. Please keep in mind this is a simplified explanation of how waste is eliminated and used as a renewable resource. It is process-oriented in breaking down fats, proteins, and other organic matter while producing energy. Ultimately, the process ends up with methane gas production. Then, the product can be scrubbed through a hydrogen sulfide scrubber, processed through gas and heat skids, and off to heat the boiler and up through a three-phase line connector to the local utilities, using a large methane generator.

Today, AD projects exist throughout the U.S., and a few brewery digesters that come to mind are Magic Hat Brewery, based out of South Burlington, VT, which is an early adopter of turning spent grain from the brewing process in biogas, used to fuel brewing operations. The digester is 42 feet high and extracts energy from spent hops, grains, and yeast. The AD system also processes the plant’s wastewater. Lagunitas Brewing Company went with Cambrian Innovation’s Ecovolt system. The system is dynamic and allows for remote management. Matt Brewing Company, led by the CEO, Nick Matt, worked with EMG International & 2Gto design the equipment & AD system on-site. Veolia is very well immersed in the AD and bioreactor space and has built large waste treatment systems around the globe. AD is not a new solution in the food & beverage industry, but it shows the example of brewing companies managing wastewater treatment projects.

Wrap-Up

Solid waste reduction goes hand in hand with a brewer’s site and operations plans.

We all love good beer, and the brewing process creates waste from cleaning out brewing vessels and aging vats daily. As they scale their production, brewer's are working hard at refining sustainability plans and carbon-neutral status.

댓글